The Edsel of Aviation Engines:

- Lycoming 0320 H2ad Operators Manual Transmission

- Lycoming H2ad Engine

- Lycoming 0320 H2ad Operator's Manual Download

LYCOMING OPERATOR’S MANUAL ATTENTION OWNERS, OPERATORS, AND MAINTENANCE PERSONNEL This operators manual contains a description of the engine, its specifications, and detailed information on how to operate and maintain it. Such maintenance procedures that may be required in conjunction with periodic inspections are also included. Department of Transportation Federal Aviation Administration 800 Independence Avenue, SW Washington, DC 20591 (866) tell-FAA ((866) 835-5322).

Not EVERY Idea can be a Winner

By Jim Cavanagh

Sitting around at AirVenture earlier this year, I spent some time with Ed Kollin, the formulation chemist who developed CamGuard. We were talking about everything (but CamGuard), when I asked him about the infamous Lycoming O-320-H2AD engine. “What was the real problem with this engine?” I asked, “Was it operator error or a design thing?”

Kollin’s response was an interesting look into the industry at that level, and his story, combined with a couple missteps at Cessna and accounts from the late Bill Thompson, dovetailed into the following tale. Enjoy!

If you own, have ever owned, or think one day you may own an airplane with the Lycoming O-320-H2AD engine, you might want to read this. Of course, nowadays most of these engines have been modified to work well or have been “fixed” chemically if you use the Lycoming additive or CamGuard. Still, you might wonder: Why in the world does Lycoming need a “fix” for one of their engines? The answer is a combination of marketing, costs, and physics; and sadly, the only ones who really paid the price for it all were the owners.

In 1968, Cessna was purchased by Textron, and an engine change was in its future. The company began using the Lycoming O-320-E2D, which was 5 hp more powerful than the Continental O-300 and it cruised 1 mph faster—a marketing coup! The engine was used for nine years, but when Cessna introduced the camber-lift wing in 1973, cruise speed went in the wrong direction—not a good thing for sales.

Well, about this time, we were also beginning to see the demise of 87 octane avgas, a.k.a. the red juice. Refineries were looking at bottom lines and were not making enough fuel for the profits they wanted. An economical out was to take a cheaper fuel and add Tetra Ethyl Lead to create 100LL. Heads soon got together and figured that if the 100LL was going to be the fuel of the future, and that higher compression engines not only could burn 100LL, but hadto burn 100LL, that it might be time to develop an engine that did not foul plugs like the older Lycomings did with the leaded fuel. Plus, if the engine could be higher compression, then it could be more powerful and make up for the speed loss of the camber-lift wing, thus killing two birds with one stone. So, if two birds, why not three? Why not design an engine that would be cheaper to build and maintain too! And that’s just what they did…sort of.

In 1977, the Cessna 172/100 (for 100 octane fuel) was introduced with the O-320-H2AD engine, boasting 160 hp. Textron had bought Cessna and already owned Lycoming, so they wanted to maximize profits by building a cheaper engine to put on an airplane that already had a market and price point. The engine, if you ever see one, looks totally different from the normal Lycoming O-320. It’s tall and skinny, has very simple sections with lots of nuts and bolts holding it together, and (most of the time) it’s painted a distinctive sky blue. Why blue? Marketing? Distinction? Who knows? Regardless, the result is an engine that not only looks sort of cheap, but is very, very different from what you’re used to. Of course, the new design also boasted those extra 10 ponies; and, if they had kept the weight the same, the performance would have been impressive.

So, Lycoming “successfully” designed an engine that could be more easily maintained. Unfortunately, even though the cam and lifters could be serviced easier, little did they know that they would have to be serviced a lot more often!

Why? To reduce costs, Lycoming used different metals for the cam and lifters. The lifters were not only made of polished cast iron, but they were changed to a barrel style, as opposed to the more traditional “mushroom” style. They also reduced the width of the cam lobe. As the name implies, the mushroom design meant that the lifter had a head/face that was considerably larger in diameter than the body, like a “T.” What they knew, but maybe didn’t realize, was that the dynamics of the cam lobe/lifter face are such that well over 100,000 psi of pressure is placed on the lifter face when the apex of the cam lobe reaches the lifter face. This kind of pressure creates heat.

We’ve been told that there’s always a barrier of oil between metal surfaces in our engines. Well, not between the cam lobe and lifter. Sure, there’s boundary oil—that is, until the apex of the lobe swipes the face, at which point all oil is squeezed out and there is metal-to-metal contact. This contact is very, very fleeting, and as soon as the lobe moves off, the pressure, ergo the temperature, begins to dissipate.

Engineers design an engine so that the high temperature is dealt with in two ways: by the surface area of the contact and the hardness of the metals that make contact. They accomplish this by hardening the surfaces (Rockwell Grading system). On all other aircraft engines, the surface area is designed to be rather generous. On the -H2AD, for cost purposes, this surface is minimal. In fact, it’s so minimal that any lessening of the surface or any defect in the interface, caused the area to be below the minimum threshold. The result is that any deformation of the lifter face or the cam lobe, including a speck of corrosion as small as a pin, causes an almost immediate process that rapidly destroys the part. This is called spalling. The result of a bad lifter face or lobe is that a cylinder will not operate properly because the valves have gotten out of time or tolerance. It creates a roughness that only replacement of the cam and lifters can fix.

Lycoming 0320 H2ad Operators Manual Transmission

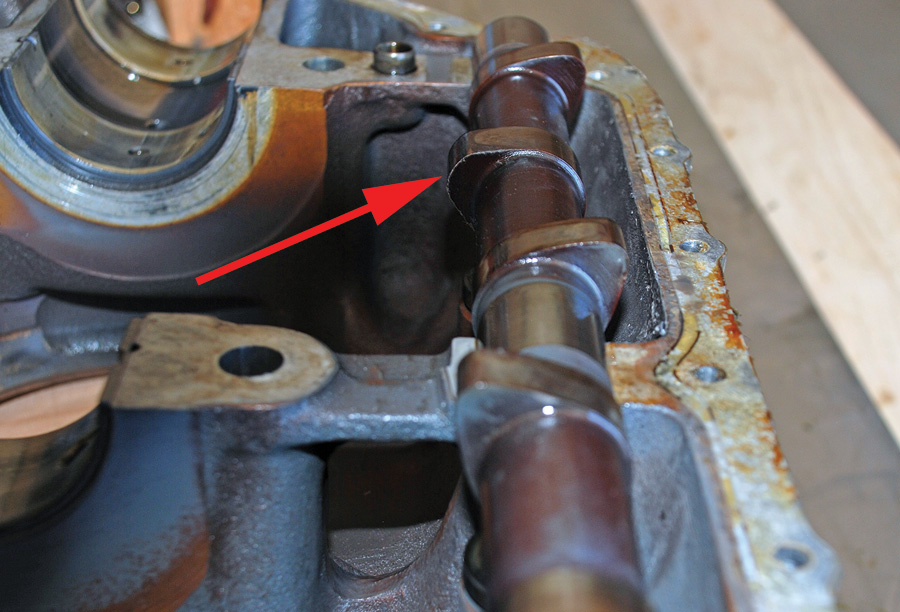

Note: The O-320-H2AD featured a less expensive, flat metal rocker. It wasn’t talked about much at the time, but mechanics have since come to realize that the rockers used in the Lycoming engine are the exact same rockers used by Ford in their 351C engine! These have millions of hours on them and have had no problems, so a lot of the Experimental guys use them at about $10 each, as opposed to around $150 per for the Lycoming parts. There are also aftermarket Roller rockers available (like those pictured here). The aviation versions are supposed to give the engine an extra 5 hp.

Lycoming H2ad Engine

Soon after pilots began complaining of failing cams and lifters, Lycoming began using an additive. The problem was approached similar to zinc in the old flat tappet cars. The Lycoming additive, LW-16702, uses chemistry to create a barrier between the two parts, easing the metal-to-metal contact and reducing wear (FAA AD 80-04-03). Comply with the AD and the engine is fixed. Note, however, there is no anti-corrosion chemistry in the Lycoming additive, unlike Shell’s 100 Plus oil, which has this additive pre-blended.

The next fix was a little bit wider camshaft lobe. The “T” mod was then developed, modifying the case so that larger diameter lifters (from .873 dia. to .950) could be installed. This did give them more surface area, but required splitting the case and some extensive work by Divco or other crankcase companies, so it was cost prohibitive for many private owners. Still, it’s a shame that after just three or four hundred hours the owners had to have new parts installed.

Lycoming had 60 variations of the O-320 engine and nearly all of them were interchangeable—except the -H model engines. They used a totally different case, camshaft, lifters, rockers and a few other parts. Cylinders were the same, but pistons were a 9.0:1 compression.

Ultimately, Cessna really took it on this chin with this engine. (And we didn’t even get into the dual magneto “issue” here. There are plenty of pro and con stories about this critter, but that wasn’t the problem that got all of the attention). Every aviation writer out there was slamming the engine, and Lycoming was losing the “bulletproof” banner it had been carrying for years. Obviously, their first slip-up was actually using the engine and getting their customers in a tizzy. However, it’s interesting (and serendipitous) that it was another Cessna “failure” that ultimately shelved the -H2AD, while it may have actually saved the venerable172!

When Cessna began developing a derivative of the 172 that was supposed to be roomier and faster, they had high hopes for a great bottom line. The 172J was to have been strutless, light, and very fast for the 150-hp engine they were planning to use. Cessna ordered 2,000 Lycoming O-320-D2J engines, with an option to buy 2,000 more. The 172J was never built; rather, it became the C-177 Cardinal.

The problem with the initial Cardinals was that they weren’t as fast as they should have been. Flight Engineer, Bill Thompson, in his wonderful book Cessna: Wings for the World, wrote that the leading edges of the wings were made of aluminum skins that were too thin, and under flight loads deformed, ruining the laminar flow. Engineers did this because the airplane was getting far too heavy. The result was a gorgeous design that flew like ten pounds of broccoli! It had visual appeal, but no numbers. Ultimately, big doors and easy entry don’t sell airplanes, but speed does.

The “fix” for the Cardinal was a 180-hp engine, and suddenly Cessna had 3000, 150-hp engines, but only one model to put them in—the 172. They immediately pulled the notorious -H2ADs and began installing the unexpectedly abundant -D2Js instead. Suddenly, everyone was happy!

Lycoming’s O-320-H2AD engines were only used on 172 N Models produced from 1977-1980, of which 8,331 were built.

There are still a lot of -H2AD engines left out there, many of which have moved to the Experimental side. If I had one of these engines, I would probably opt for using CamGuard rather than the Lycoming additive (regardless of the AD); simply because of the hours we are NOT flying these days and the anti-corrosion/anti-wear chemistry of the product.

So, between the “T” mod, the Lycoming additive, and CamGuard, these engines should be dependable these days. To check this, I called Bobby Merrell of Aircraft Specialties Services, an aviation machine shop that overhauls engine parts. “Of this particular engine,” he told me, “you’ll either see a pristine, nearly perfect engine, or one that is all ate up and needs everything replaced.”

Backing Merrell’s comments, chatroom after chatroom has pilots saying that if you run the engine to temp a couple of times a week it will last forever. In fact, Ed Kollin told me that if you would start an -H2AD engine and never shut it down, while somehow keeping fresh oil in the case, it could go for 4,000 hours! Conversely, if you let this particular engine sit for extended periods it seems doomed to develop a failed cam or lifter.

What I get from these comments is that things probably haven’t changed all that much. Regardless, I think an owner can be conscientious and do everything he or she can to keep the engine healthy. If you fly a lot and follow all of the instructions, you might get years of operation out of the engine. After all, the Experimental guys don’t complain about them—then again, they do a lot of their own work and don’t have to be as legal as we do.

This piece wasn’t about how to treat an engine, or how to fly it, so much as it’s a discussion of a particular engine and its place in aviation history. In short, the -H2AD is notorious: you will NOT find Superior or ECI replicating this particular design! Ford had the Edsel. Frances Ford Coppola had Heaven’s Gate, Coke had New Coke, and Lycoming, builder of some of the world’s best aircraft engines, had the -H2AD. Not everything can be a winner. But, hey, you could have a Mooney with a Porsche engine in it!

Find your aircraft application below and tap for engine quote

Lycoming 0320 H2ad Operator's Manual Download

| Alpha Aviation Lycoming O-320-D2A Reference: 10354 |

| American Champion 7GCBC Citabria Lycoming O-320-B2B 12 Volt System | Reference: 9346 |

| American Champion 7GCAA Citabria Lycoming O-320-B2B 12 Volt System | Reference: 9346 |

| Apex - Robin Lycoming O-320-D1A 12 Volt System | Reference: 8609 |

| Apex - Robin DR400 160 Regent Lycoming O-320-D2A 12 Volt System | Reference: 8421 |

| Apex - Robin Lycoming O-320-D2A Reference: 9767 |

| Apex - Robin DR-300 - 140 Petit Prince Lycoming O-320-E2A 12 Volt System | Reference: 8611 |

| Apex - Robin DR400 160 Regent Lycoming O-320-D2A 12 Volt System | Reference: 9634 |

| Avcon Conversion Lycoming O-320-E2D 12 Volt System | Reference: 8797 |

| Avcon Conversion Lycoming O-320-E2D 12 Volt System | Reference: 9695 |

| Avid Magnum Lycoming O-320-E2D 12 Volt System | Reference: 9301 |

| Beagle PUP-150 Lycoming O-320-A2B 12 Volt System | Reference: 9379 |

| Beech M-23 Musketeer Lycoming O-320-D2B 12 Volt System | Reference: 8625 |

| Beech B23-19 Musketeer III Lycoming O-320-E2C 12 Volt System | Reference: 8564 |

| Beech B-19 Sport Lycoming O-320-E3D 12 Volt System | Reference: 8032 |

| Bellanca 7GCBC Citabria Lycoming O-320-A2B 12 Volt System | Reference: 9379 |

| Bellanca 7GCBC Citabria Lycoming O-320-A2D 12 Volt System | Reference: 8822 |

| Cessna 170 Doynr Conversion Lycoming O-320-B1A 12 Volt System | Reference: 9467 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J Reference: 8164 |

| Cessna C-152 Conversion Lycoming O-320-E2D 24 Volt System | Reference: 8031 |

| Cessna C-172 Skyhawk Lycoming O-320-E2D 12 Volt System | Reference: 8181 |

| Cessna C-172 Lycoming O-320-E2D 12 Volt System | Reference: 8888 |

| Cessna C-172 Skyhawk Lycoming O-320-E2D 12 Volt System | Reference: 9947 |

| Cessna C-172-N Skyhawk Lycoming O-320-H2AD 24 Volt System | Reference: 7396 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 12 Volt System | Reference: 8373 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 24 Volt System | Reference: 9677 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 24 Volt System | Reference: 9684 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 24 Volt System | Reference: 9796 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 12 Volt System | Reference: 9864 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J Reference: 10153 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 24 Volt System | Reference: 10640 |

| Cessna C-172 Skyhawk Lycoming O-320-D2J 24 Volt System | Reference: 10681 |

| Cessna C-172 Lycoming O-320-E2D 12 Volt System | Reference: 9820 |

| Cessna C-172 Lycoming O-320-E2D 12 Volt System | Reference: 10495 |

| Cessna C-177 Cardinal Lycoming O-320-E2D N/ Volt System | Reference: 10213 |

| Cessna C-172 Skyhawk Lycoming O-320-E2D 12 Volt System | Reference: 9668 |

| Cessna C-172 Skyhawk Lycoming O-320-E2D 12 Volt System | Reference: 9794 |

| Cessna C-172 Skyhawk Lycoming O-320-E2D 12 Volt System | Reference: 9847 |

| Cessna 172 Lycoming O-320-H2AD Reference: 10282 |

| Cessna C-172-N Skyhawk Lycoming O-320-H2AD 12 Volt System | Reference: 7403 |

| Cessna C-172-N Skyhawk Lycoming O-320-H2AD 12 Volt System | Reference: 9837 |

| Cessna C-172-N Skyhawk Lycoming O-320-H2AD 24 Volt System | Reference: 9852 |

| Cub Crafters Lycoming O-320-B2B 12 Volt System | Reference: 9757 |

| Euro-Enaer Lycoming O-320-D2A Reference: 9923 |

| F. F. A. AS-202 Bravo Lycoming O-320-D2A 12 Volt System | Reference: 8551 |

| F. F. A. AS-202 Bravo Lycoming O-320-E2A 12 Volt System | Reference: 9321 |

| Fuji FA-200-160 Lycoming O-320-D2A 12 Volt System | Reference: 8610 |

| Grob G115B - G115C Lycoming O-320-D1A 24 Volt System | Reference: 8978 |

| Grob G-115 Lycoming O-320-E1A 12 Volt System | Reference: 8431 |

| Grumman GA-7 Cougar Lycoming O-320-D1D 12 Volt System | Reference: 8144 |

| Grumman AA5 Traveler Lycoming O-320-E2G 12 Volt System | Reference: 8092 |

| Grumman GA-7 Cougar Lycoming O-320-D1D 12 Volt System | Reference: 9776 |

| Grumman AA5 Traveler Lycoming O-320-E2G 12 Volt System | Reference: 9738 |

| Gyroflug SC-01B Speed Canard Lycoming O-320-D1A 12 Volt System | Reference: 8508 |

| Lancair Lancair 320 Lycoming O-320-D1F 12 Volt System | Reference: 8786 |

| MBB BO-209-B Lycoming O-320-E1F 12 Volt System | Reference: 8997 |

| MBB BO-209-B Lycoming O-320-E2F 12 Volt System | Reference: 9619 |

| Partenavia P-66B Oscar Lycoming O-320-E2A 12 Volt System | Reference: 8923 |

| Partenavia P-66C Lycoming O-320-H2AD 12 Volt System | Reference: 7259 |

| Penn Yan Aero STC Lycoming O-320-D3G 12 Volt System | Reference: 9532 |

| Piper PA-25 Pawnee Lycoming O-320-A2A 12 Volt System | Reference: 8989 |

| Piper PA-18-150 Super Cub Lycoming O-320-A2B 12 Volt System | Reference: 8553 |

| Piper PA-28-150 Cherokee Lycoming O-320-A2B 12 Volt System | Reference: 8624 |

| Piper PA-28-150 Cherokee Lycoming O-320-A2B 12 Volt System | Reference: 10055 |

| Piper PA-23 Apache Lycoming O-320-A3A 12 Volt System | Reference: 9393 |

| Piper PA-23 Apache Lycoming O-320-A3B 12 Volt System | Reference: 9384 |

| Piper PA-22-160 Tri-Pacer Lycoming O-320-B2A 12 Volt System | Reference: 9812 |

| Piper PA-22-160 Tri-Pacer Lycoming O-320-B2B 12 Volt System | Reference: 8493 |

| Piper PA-18 Wings Unlimited Conversion Lycoming O-320-B2B 12 Volt System | Reference: 9514 |

| Piper PA-18 Wings Unlimited Conversion Lycoming O-320-B2B 12 Volt System | Reference: 10428 |

| Piper PA-28-160 Tri-Pacer Lycoming O-320-B2B 12 Volt System | Reference: 9892 |

| Piper PA-23-160 Apache Lycoming O-320-B3B 12 Volt System | Reference: 8587 |

| Piper PA-23-160 Apache Lycoming O-320-B3B 24 Volt System | Reference: 10135 |

| Piper PA-28-160 Cherokee Lycoming O-320-D2A 12 Volt System | Reference: 8589 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 8150 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 8446 |

| Piper PA-28-161 Warrior III Lycoming O-320-D3G 24 Volt System | Reference: 8585 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 8885 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 9792 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 9910 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 10316 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 10665 |

| Piper PA-28-140 Cherokee Cruiser Lycoming O-320-E2A 12 Volt System | Reference: 8590 |

| Piper PA-28-140 or PA-28-150 Cherokee Lycoming O-320-E2A 12 Volt System | Reference: 8903 |

| Piper PA-22 Tri-Pacer Lycoming O-320-E3D 12 Volt System | Reference: 9546 |

| Piper PA-28-151 or PA-28-140 Warrior Lycoming O-320-E3D 12 Volt System | Reference: 8310 |

| Piper PA-28-140 Cherokee Lycoming O-320-E3D 12 Volt System | Reference: 9665 |

| Piper PA-28-150 Cherokee Lycoming O-320-A2B 12 Volt System | Reference: 9971 |

| Piper PA-18-150 Super Cub Lycoming O-320-A2B 12 Volt System | Reference: 9802 |

| Piper PA-22-160 Tri-Pacer Lycoming O-320-B2B 12 Volt System | Reference: 9645 |

| Piper PA-22-160 Tri-Pacer Lycoming O-320-B2B Reference: 9932 |

| Piper PA-18 Wings Unlimited Conversion Lycoming O-320-B2B 12 Volt System | Reference: 10171 |

| Piper PA-23-160 Apache Lycoming O-320-B3B 12 Volt System | Reference: 9850 |

| Piper PA-23-160 Apache Lycoming O-320-B3B 12 Volt System | Reference: 9870 |

| Piper PA-28-160 Cherokee Lycoming O-320-D2A 12 Volt System | Reference: 9676 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 9649 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 10180 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 10445 |

| Piper PA-28-161 Cadet Lycoming O-320-D3G 12 Volt System | Reference: 10571 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 9905 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 10078 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G Reference: 10172 |

| Piper PA-28-161 Warrior II Lycoming O-320-D3G 12 Volt System | Reference: 10447 |

| Piper PA-28-161 Warrior III Lycoming O-320-D3G 24 Volt System | Reference: 10300 |

| Piper PA-28-161 Warrior III Lycoming O-320-D3G 24 Volt System | Reference: 10345 |

| Piper PA-28-161 Warrior III Lycoming O-320-D3G 24 Volt System | Reference: 10701 |

| Piper PA-28-140-150 Cherokee Lycoming O-320-E2A 12 Volt System | Reference: 9744 |

| Piper PA-28-151 Warrior Lycoming O-320-E3D 12 Volt System | Reference: 9773 |

| Ram Aircraft C-172 Skyhawk STC Lycoming O-320-D2J 24 Volt System | Reference: 10380 |

| Riley C-172 Ram Conversion - Skyhawk Lycoming O-320-D2G 24 Volt System | Reference: 8024 |

| Riley Ram Conversion - Cessna Lycoming O-320-D2G 12 Volt System | Reference: 8372 |

| Riley C-172 Ram Conversion - Skyhawk Lycoming O-320-D2G 24 Volt System | Reference: 10182 |

| Riley Ram Conversion - Cessna Lycoming O-320-D2G Reference: 10156 |

| Riley C-172 Ram Conversion - Skyhawk Lycoming O-320-D2G 24 Volt System | Reference: 10240 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 8864 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 9715 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 8656 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 8940 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 9752 |

| Robinson R-22B Lycoming O-320-B2C 12 Volt System | Reference: 9860 |

| Slingsby T67C Lycoming O-320-D2A 24 Volt System | Reference: 8438 |

| SOCATA TB-9 Lycoming O-320-D1A 12 Volt System | Reference: 9650 |

| SOCATA TB-9 Lycoming O-320-D1A 12 Volt System | Reference: 9746 |

| SOCATA TB-9 Tampico Lycoming O-320-D2A 24 Volt System | Reference: 8562 |

| SOCATA TB-9 Tampico Lycoming O-320-D2A 12 Volt System | Reference: 8596 |

| SOCATA TB-9 Tampico Lycoming O-320-D2A 24 Volt System | Reference: 8748 |

| SOCATA MS-892 Rallye 150 Lycoming O-320-E2A 12 Volt System | Reference: 8626 |

| SOCATA TB-9 Tampico Lycoming O-320-D2A 12 Volt System | Reference: 10006 |

| Stoddard Hamilton Glasair Super II S Lycoming O-320-D1A 12 Volt System | Reference: 8833 |

| Stoddard Hamilton Glastar Lycoming O-320-D1F 12 Volt System | Reference: 9454 |

| Sud GY80-160 Gardan Lycoming O-320-B3B 12 Volt System | Reference: 10135 |

| Vans RV Lycoming O-320-D1A 12 Volt System | Reference: 8760 |

| Varga 2150A Kachina Lycoming O-320-A2C 12 Volt System | Reference: 8821 |

| Wassmer WA-52 Lycoming O-320-D1F 12 Volt System | Reference: 8556 |

| Wassmer Lycoming O-320-E2C 12 Volt System | Reference: 10164 |